Pioneering

MEDICAL WASTE TREATMENTFrom hospital to recycling company

Shredding Hazardous Waste, Sterilizing, Saving Costs— for Every Scale.

MACS High-End Autoclaves transform hazardous waste into safe, volume-reduced residual waste — without chemicals or complex maintenance. Designed for both healthcare (hospitals, clinics, laboratories) and waste management operations, our solutions handle medical waste, food waste, and liquids, whether stationary or mobile. The result: minimal disposal costs, 24/7 remote support, and a measurable positive environmental impact.

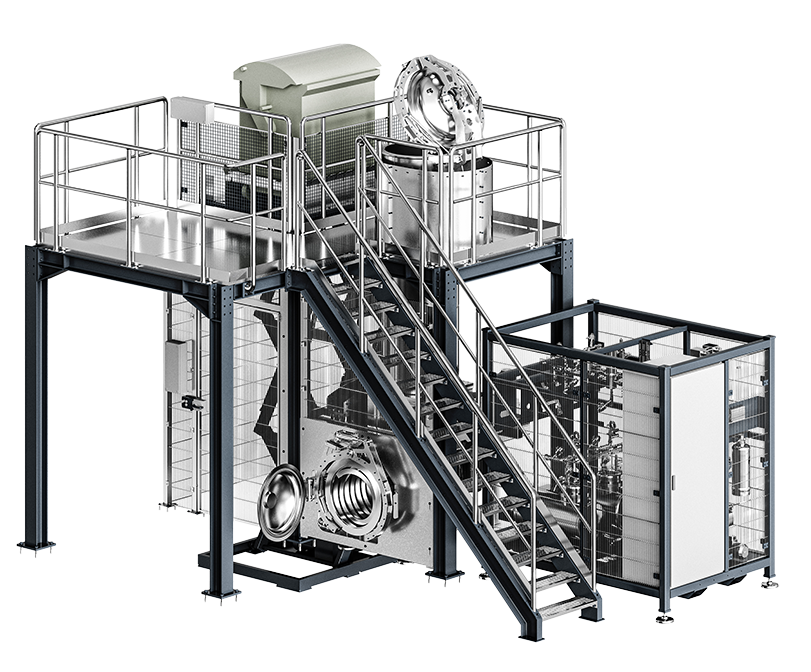

Industrial Series

Maximum Capacity, Heavy-Duty Performance

For high-volume processing in central sterilization facilities and waste management plants. Engineered for continuous operation, handling large waste streams efficiently and sustainably. Ideal for centralized waste treatment hubs where reliability and throughput are critical. Combines industrial-scale throughput with exceptional energy and resource efficiency.

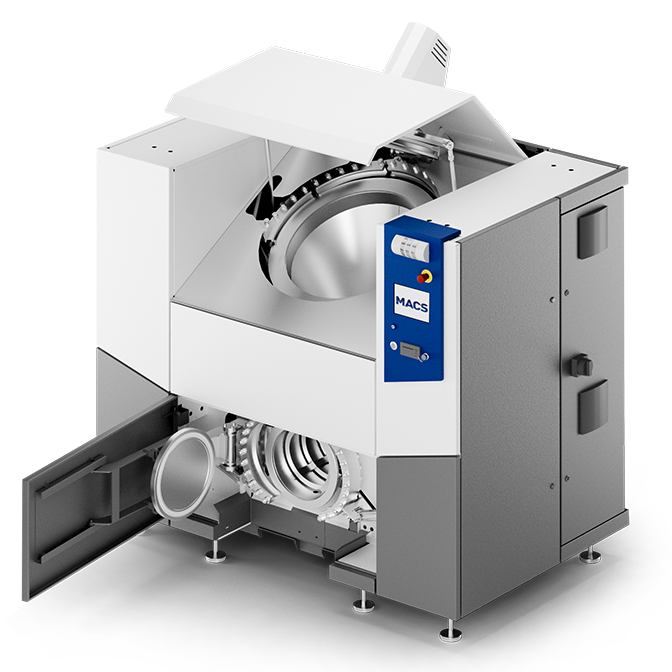

Compact Series

Efficiency in Every Dimension.

For smaller facilities, hospitals, clinics, laboratories, and local waste handlers who need efficient sterilization in a compact footprint. Offers the same advanced technology and sterilization performance as our industrial systems, engineered for fast, reliable results in flexible environments.

Compact Series

Efficiency in Every Dimension.

For smaller facilities, hospitals, clinics, laboratories, and local waste handlers who need efficient sterilization in a compact footprint. Offers the same advanced technology and sterilization performance as our industrial systems, engineered for fast, reliable results in flexible environments.

FROM HOSPITAL TO WASTE RECYCLING COMPANY

Use MACS Autoclaves for Your Specific Application.

Whether a compact autoclave with a 125-liter capacity or a large custom-made system of up to 2500 liters: MACS sterilizes worldwide in doctors’ offices, laboratories, airports, hospitals, waste management facilities, recycling companies, and more. Stationary or mobile, in field operations and at sea – ready wherever safe waste treatment is needed.

Your New Secure Number:

Exceed international SAL standards by a factor of multiple times.

The SAL – Sterilization Assurance Level – defines the internationally recognized safety level for the effectiveness of sterilization procedures in killing germs. The WHO recommends SAL = 10-6. However, MACS autoclaves sterilize waste up to eight times more securely, with a SAL = 10-48.

3 Programs for Every Situation

Sterilize infectious waste, food waste, and liquids — with precision.

Every MACS Autoclave offers dedicated, pre-set programs to ensure optimal treatment of hazardous waste in any environment — from hospitals and laboratories to waste management facilities and recycling plants. Each program is engineered for reliable sterilization, minimal energy consumption, and full compliance with international safety and environmental standards.

Save On-site:

Reduce your disposal costs

By A Factor Of

7 to 10

Your waste disposal company will not be happy to hear this:

Instead of costly hazardous waste, only low-cost residual waste and wastewater remain after treatment with MACS-Autoclave. The integrated volume reduction by up to 97% saves valuable space and makes further waste handling significantly more efficient.

Intuitive Operation,

Reliable Service

Make Sustainability Simple.

MACS-Autoclaves come as straightforward plug-and-play solutions. Just connect to power, water supply, and wastewater, and start operating. If technical issues do occur, you won’t be left waiting long: MACS Remote Service quickly gets your autoclave back on track digitally.

Benefits at a Glance

Find numerous other advantages for your application.

We will be happy to advise you on how your organization can benefit sustainably from MACS-Autoclaves – economically and ecologically. Simply arrange a personal demo call.

Effectiveness

Achieves up to 97% waste volume reduction. Offers the best sterilization-to-energy consumption ratio in its class.

User-Friendliness

Ergonomic and Safe, Standardized Connections, Remote Support Options.

Sustainability

Chemical-Free Operation, Energy-Efficient, Volume Reduction, Emission-Free.

Reliability

Chemical-Free Operation, Energy-Efficient, Volume Reduction, Emission-Free.

Financial Benefits

Continuous Operation, Power Outage Safety, Independent of External Services.

MACS Models:

MACS XLP

- Volume of the filling hopper: 125 liters

- Process capacity per cycle*: 250 litres / 25 – 75 kg

(Density 0.1 – 0.3 kg/l) - Height/Width/Depth: 2090 / 2120 / 1570 mm

- Energy consumption: Average 17.5 kW

3 phases, 400 V, 50 Hz – 60 Hz

* Process time: Standard 60 minutes.

MACS 135

Available as a maritime version upon request.

- Volume of the filling hopper: 135 liters

- Process capacity per cycle*: 270 liters / 27 – 81 kg

(Density 0.1 – 0.3 kg/l) - Height/Width/Depth: 2300 / 2200 / 1400 mm

- Energy consumption: Durchschnittlich 17.5 kW

3 Phasen, 400 V, 50 Hz – 60 Hz

* Process time: Standard 60 minutes.

MACS 300

- Volume of the filling hopper: 350 liters

- Process capacity per cycle*: 300 liters / 30 – 90 kg

(Density 0.1 – 0.3 kg/l) - Height/Width/Depth: 2850 / 2800 / 1550 mm

- Energy consumption: Average 25 kW

3 phases, 400 V, 50 Hz – 60 Hz

* Process time: Standard 60 minutes.

MACS 500

- Volume of the filling hopper: 500 liters

- Process capacity per cycle*: 500 liters / 50 – 150 kg

(Density 0.1 – 0.3 kg/l) - Height/Width/Depth: 3370 / 2800 / 1850 mm

- Energy consumption: Average 27 kW

3 phases, 400 V, 50 Hz – 60 Hz

* Process time: Standard 60 minutes.

MACS 700

Available with a 4-shaft shredder upon request.

- Volume of the filling hopper: 350 liters

- Process capacity per cycle*:

700 liters / 70 – 210 kg

(Dichte 0,1 – 0,3 kg/l) - Height/Width/Depth: 3370 / 2800 / 1850 mm

- Energy consumption: Average 30 kW

3 phases, 400 V, 50 Hz – 60 Hz

* Process time: Standard 60 minutes.

MACS 800

- Volume of the filling hopper: 400 liters

- Process capacity per cycle*: 800 liters / 80 – 240 kg

(Density 0.1 – 0.3 kg/l) - Height/Width/Depth: 2950 / 2700 / 1950 mm

- Energy consumption: Average 30 kW

3 phases, 400 V, 50 Hz – 60 Hz

* Process time: Standard 60 minutes.

MACS 1050 – 2500

Custom industrial solutions

- Volume of the filling hopper: up to 2500 liters

- Process capacity per cycle*: up to 2500 liters/ 750 kg

(Density 0.1 – 0.3 kg/l) - Height/Width/Depth: customized

- Energy consumption: Average 50 – 85 kW

3 phases, 400 V, 50 Hz – 60 Hz

* Process time: Standard 60 minutes.