Which

MACS model

… suits your needs?

Key factors in choosing the right MACS-Autoclave:

Selecting the right MACS-Autoclave for your facility requires an understanding of your specific operational requirements and waste characteristics:

Waste volume and bulk density

The volume and density of your waste will determine the required processing capacity of the MACS-Autoclaves. This determines how much waste can be effectively processed in a given time frame.

Waste type

Different types of waste require different processing cycles. Knowing whether the waste is predominantly medical, infectious or other types of waste is crucial to selecting a machine with the correct programme settings and capacity to handle the expected load.

Operating conditions:

Factors such as number of shifts, operating hours and staff availability are essential. These aspects influence the choice of MACS machine in terms of automation, speed and ease of use to seamlessly integrate waste treatment into your facility’s workflow.

Contact us for a customised solution:

Ready to improve your operational efficiency with a MACS-Autoclave? Contact our team for expert advice and to tailor a system that integrates seamlessly into your facility’s operations.

Next steps:

To ensure you select the most suitable MACS machine for your needs, consider a detailed consultation with our specialists. Understanding your specific waste output, operational patterns and staff workflows will help to tailor the right solution. We invite you to complete our detailed questionnaire or contact us directly to start optimising your waste management strategy.

Calculation examples

MACS XLP

Waste amount (t/year): 70

Waste density (kg/l): 0.625

Annual savings (€): 105,000

Payback period (years): 2,39

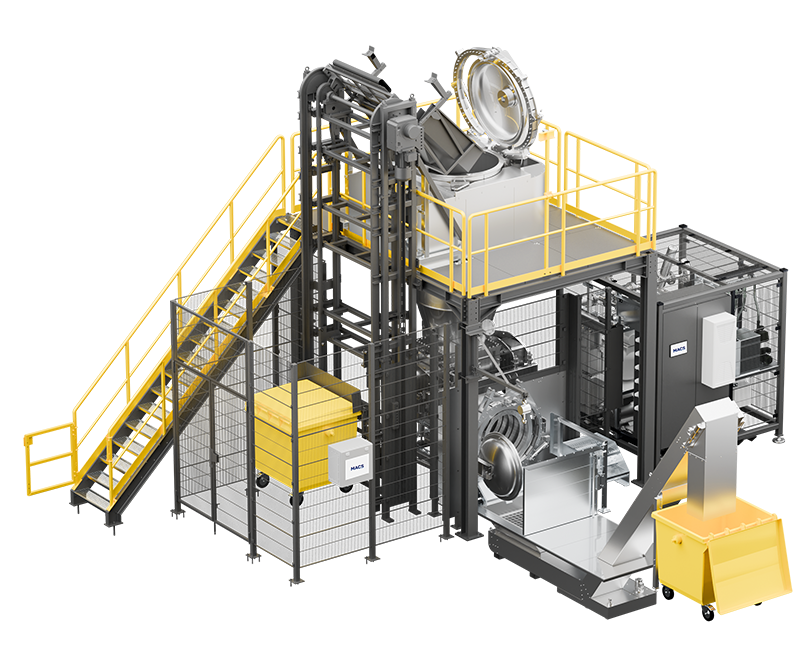

MACS 700

Waste amount (t/year): 300

Waste density (kg/l): 0.35

Annual savings (€): 398,571

Payback period (years): 0.91

MACS 1050

Waste amount (t/year): 500

Waste density (kg/l): 0.3

Annual savings (€): 616,667

Payback period (years): 0.77

MACS 2500

Waste amount (t/year): 1,000

Waste density (kg/l): 0.15

Annual savings (€): 900,000

Payback period (years): 1,59

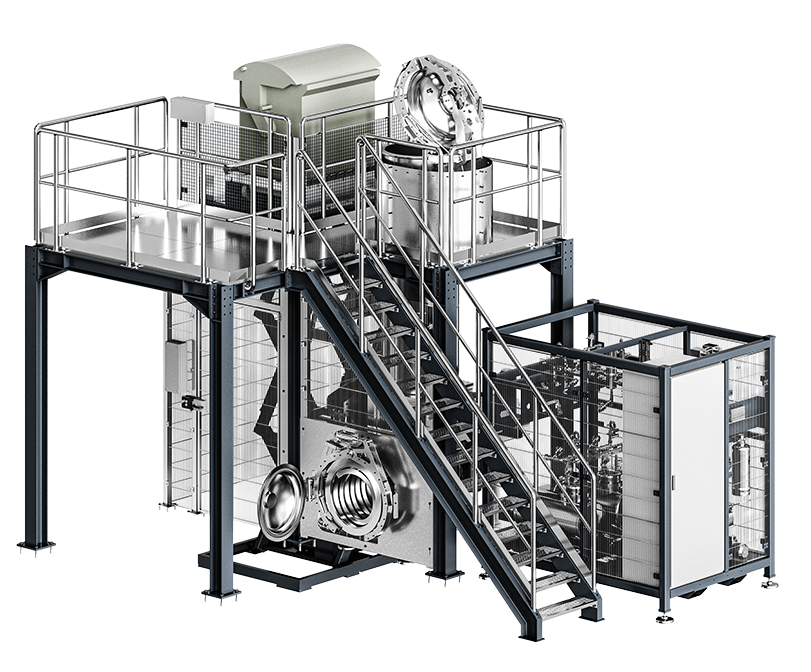

MACS Series Overview

MACS model |

MXLP |

M135 |

M300 |

M500 |

M700 |

M800 |

M1050 |

M2500 |

Incineration** |

|---|---|---|---|---|---|---|---|---|---|

MACS modelVolume of Feed Hopperin l |

MXLP125 |

M135135 |

M300350 |

M500500 |

M700350 |

M800400 |

M10501.050 |

M25002.500 |

Incineration**depending on the system |

MACS modelProcess Capacity per Cycle(Density 0,1 – 0,3 kg/l) in kg |

MXLP25-75 |

M13527-81 |

M30030-90 |

M50050-150 |

M70070-210 |

M80080-240 |

M1050105-315 |

M2500250-750 |

Incineration**depending on the system |

MACS modelProcess Capacity/24h(18 Cycles, theoretical max.) in l |

MXLP4.500 |

M1354.860 |

M3005.400 |

M5009.000 |

M70012.600 |

M80014.400 |

M105018.900 |

M250045.000 |

Incineration**depending on the system |

MACS modelVolume reduction potential*per year in l

|

MXLP65.700 |

M13570.956 |

M300178.704 |

M500262.800 |

M700367.920 |

M800420.480 |

M1050551.880 |

M25001.314.000 |

Incineration**100% plus CO2 |

MACS modelEco Balance |

MXLP

|

M135

|

M300

|

M500

|

M700

|

M800

|

M1050

|

M2500

|

Incineration**

|

MACS modelEnergy balance |

MXLP

|

M135

|

M300

|

M500

|

M700

|

M800

|

M1050

|

M2500

|

Incineration**

|

MACS modelCO₂ reduction potentialper 600km in t |

MXLP2.759 |

M1352.980 |

M3007.506 |

M50011.038 |

M70015.453 |

M80017.660 |

M105023.179 |

M250055.188 |

Incineration**Zero |

MACS modelCO₂ emissionper year in t |

MXLPZero |

M135Zero |

M300Zero |

M500Zero |

M700Zero |

M800Zero |

M1050Zero |

M2500Zero |

Incineration**340.000 |

MACS modelwaste reduction(depending on waste type and density) in %

|

MXLPup to 97 |

M135up to 97 |

M300up to 97 |

M500up to 97 |

M700up to 97 |

M800up to 97 |

M1050up to 97 |

M2500up to 97 |

|

MACS modelTypical annual waste volume***in t |

MXLP75 |

M13581 |

M30090 |

M500150 |

M700218 |

M800240 |

M1050330 |

M2500750 |

Incineration**depending on the system |

MACS model |

MXLP |

M135 |

M300 |

M500 |

M700 |

M800 |

M1050 |

M2500 |

Incineration** |

|

|---|---|---|---|---|---|---|---|---|---|---|

MACS modelVolume of Feed Hopper |

MXLP125 |

M135135 |

M300350 |

M500500 |

M700350 |

M800400 |

M10501.050 |

M25002.500 |

Incineration**depending on the system |

|

MACS modelProcess Capacity per Cycle (in kg)(Density 0,1 – 0,3 kg/l) |

MXLP25-75 |

M13527-81 |

M30030-90 |

M50050-150 |

M70070-210 |

M80080-240 |

M1050105-315 |

M2500250-750 |

Incineration**depending on the system |

|

MACS modelProcess Capacity/24h (in l)(18 Cycles, theoretical max.) |

MXLP4.500 |

M1354.860 |

M3005.400 |

M5009.000 |

M70012.600 |

M80014.400 |

M105018.900 |

M250045.000 |

Incineration**depending on the system |

|

MACS modelVolume reduction* p.a. (in l) |

MXLP65.700 |

M13570.956 |

M300178.704 |

M500262.800 |

M700367.920 |

M800420.480 |

M1050551.880 |

M25001.314.000 |

Incineration**100% plus CO2 |

|

MACS modelEco Balance |

MXLP

|

M135

|

M300

|

M500

|

M700

|

M800

|

M1050

|

M2500

|

Incineration**

|

|

MACS modelEnergy balance |

MXLP

|

M135

|

M300

|

M500

|

M700

|

M800

|

M1050

|

M2500

|

Incineration**

|

|

MACS modelCO₂ reduction potential (in t)per 600km |

MXLP2.759 |

M1352.980 |

M3007.506 |

M50011.038 |

M70015.453 |

M80017.660 |

M105023.179 |

M250055.188 |

Incineration**Zero |

|

MACS modelCO₂ emission per year (in t) |

MXLPZero |

M135Zero |

M300Zero |

M500Zero |

M700Zero |

M800Zero |

M1050Zero |

M2500Zero |

Incineration**340.000 |

|

MACS modelwaste reduction (in %)(depending on waste type and density) |

MXLPup to 97 |

M135up to 97 |

M300up to 97 |

M500up to 97 |

M700up to 97 |

M800up to 97 |

M1050up to 97 |

M2500up to 97 |

Incineration**none |

|

MACS modelTypical annual waste volume*** (in t) |

MXLP75 |

M13581 |

M30090 |

M500150 |

M700218 |

M800240 |

M1050330 |

M2500750 |

Incineration**depending on the system |

* Calculated on the basis of the MACS Liquid Program

** Standard data for an Austrian waste incineration plant as of May 2023, carbon dioxide equivalents caused by waste treatment in Vienna as of 2016, source: www.wien.gv.at/umwelt/ma48

Copyright 2024: Ermafa Environmental Technologies, independent source: Typographical errors reserved

***: 50 working weeks/year, 5 working days/week, 6 cycles/day